How Does Laser Cleaning Work?

Today, as industries and maintenance sectors are constantly seeking more efficient and environmentally friendly solutions, laser cleaning has quickly become one of the most popular surface treatment methods.

Unlike traditional abrasive or chemical cleaning techniques, a laser removes contaminants precisely, contact-free, and without the use of chemicals.

But how exactly does it work? Below, we explain in simple terms what makes laser cleaning such a smart and effective technology.

What Is Ablation?

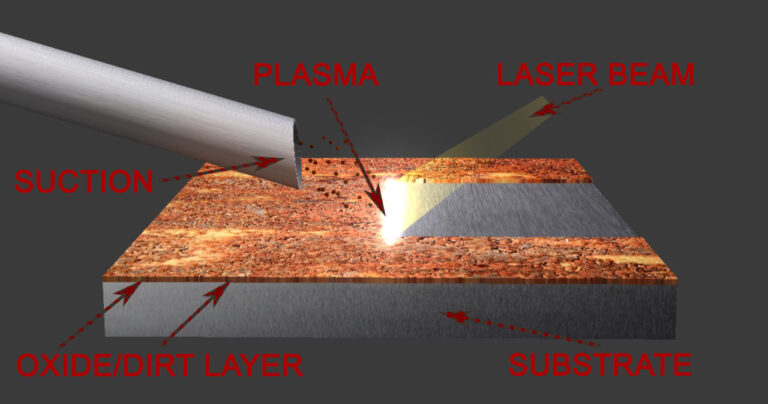

Ablation refers to the removal of material from a surface through evaporation, sublimation, or erosion using an energy source — in this case, a laser.

In laser cleaning, this phenomenon is known as laser ablation — a process in which a high-energy laser beam vaporizes or breaks down the contaminant layer, leaving the underlying metal or other material completely intact.

How Laser Cleaning Works?

The laser beam is directed onto the surface using galvanometers, or mirror motors, located inside the laser head. This allows for fast and precise scanning even over large areas.

Since the laser works entirely without physical contact, there is no mechanical wear, and the surface remains untouched.

No abrasive materials or chemicals are required, making the method safe, clean, and environmentally friendly.

Conclusion

Laser cleaning is a fast, precise, and cost-effective way to remove rust, paint, oil, and other contaminants without damaging the base material.

This technology combines the precision of physics, high reliability, and sustainability, providing effective solutions for industrial, restoration, and maintenance applications.

Laser cleaning is not just a new trend — it is the cleaning solution of the future, making surface treatment cleaner, safer, and more efficient than ever before.